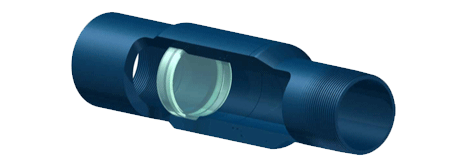

Disappearing Glass Casing Flotation Sub

Overview

Our Completion Energy’s Debris-free, Disappearing Glass Flotation Sub allows operators to float casing to bottom in long laterals. The casing section below the sub is purposely left empty allowing the buoyancy force to reduce any friction along the lateral while the weight of fluid above the sub helps pushing the casing to bottom.

OPERATION

- Using a floating casing system in long laterals can eliminate the need to rotate the casing string to the bottom, which can also eliminate the need for premium casing threads. The flotation sub is installed and run as an integrated part of the casing string. This assembly increases the efficiency of the installation process with the benefit of having the full bore access once the sub is removed.

- The patented laminated-glass material provides a secure, non-corrodible seal under high temperature and axial loads, capable of withholding extreme levels of differential pressure across the tool. Upon removal, the glass material breaks into minute particles which can be safely and efficiently be circulated through sleeves, toe valves, and other equipment. No debris trap nor landing collar is needed with this tool.

FEATURES AND BENEFITS

- No debris trap or landing collar are needed

- High debris tolerance

- Full bore access

- Customer specified activation pressure

- No personnel requirement

- No impact on cementing operation or downhole equipment

- Reduce casing running time

- No special cementing plugs are needed

- Shorter shoe track, more pay zone available